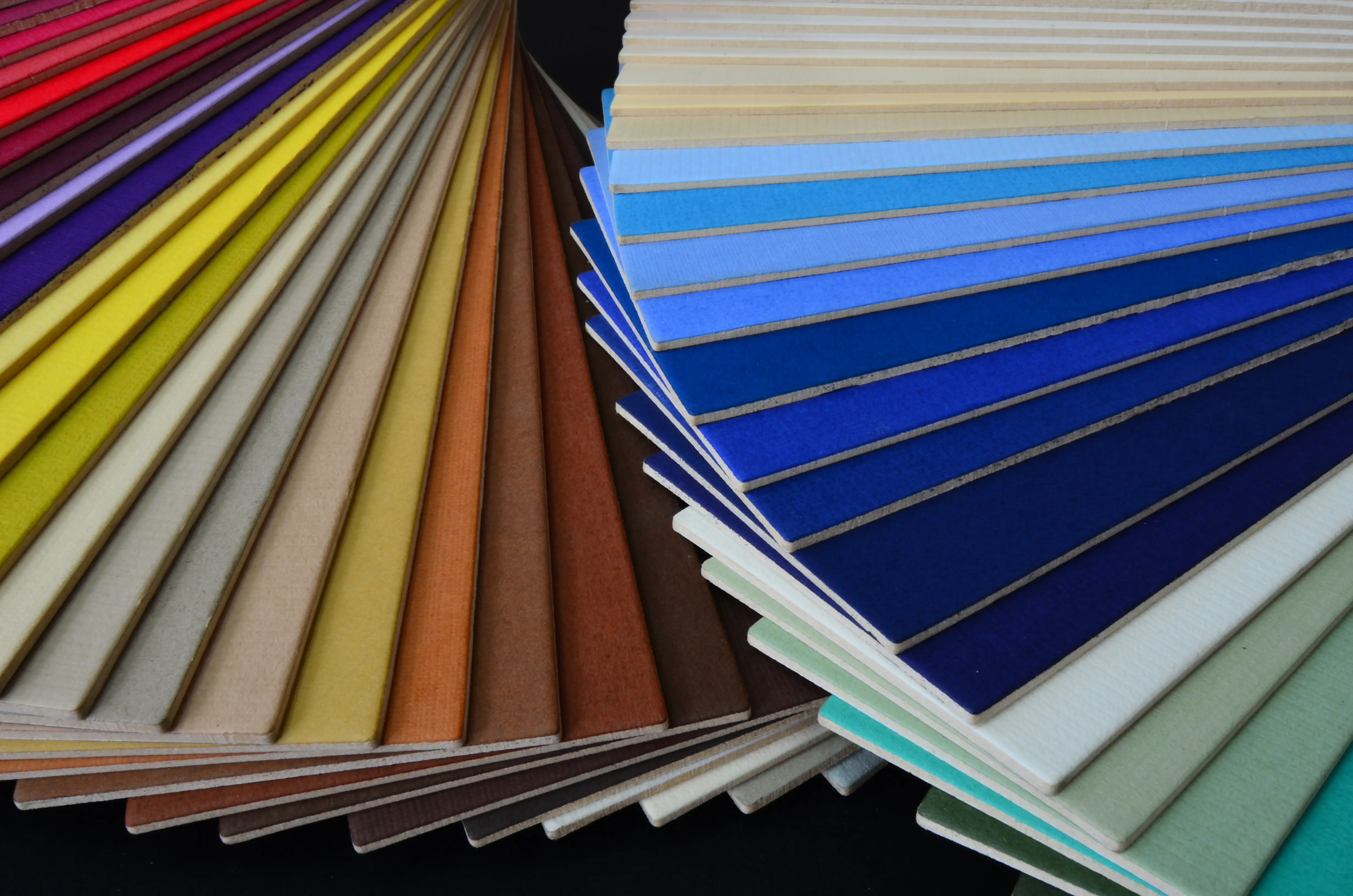

In custom framing, matting sets the tone for the entire piece. It helps carve out space around the art, create depth, and guide the viewer’s eye — all while protecting the work.

The right matting techniques also increase revenue. When priced with materials, labor, and design complexity in mind, they can turn a basic frame job into a high-margin service.

In this post, we cover how different matting styles affect pricing — and offer tips for presenting upgrades that benefit both your client and your bottom line.

Profit Margins by Mat Type: How Each Layer Adds Value

Adding matting to a custom frame project increases the visual impact and the sale price. On average, a frame that includes matting — compared to a frame with glass and moulding only — can generate 35% to 45% more revenue, even with standard materials.

The more detailed the matting technique, the higher your markups:

- Offer a single mat for gains of around 40% to 50%

- Upgrade to a double mat for between a 60% and 70% cushion

- Build a triple mat design to reach 70% to 80% or more

Additional matting layers take more time and material, which justifies higher prices and bigger net sales per job.

Why Premium Matting Commands Higher Prices

Higher mat counts change how the piece looks and expand the scope of the work. Each added layer increases the time spent and material used, especially with double and triple mat designs.

These elements justify the bigger return for your shop:

-

Add labor time: Cut, align, and clean each layer accurately — what takes 10 minutes for a single mat can stretch to 30 minutes with a triple.

-

Use more materials: Stack multiple layers of matboard, increasing raw material use, bevel wear, and potential waste from miscuts.

-

Rely on design expertise: Plan color reveals, spacing, and proportions to achieve visual depth — customers often pay more for design decisions they can’t make on their own.

-

Create visual depth: Increase the dimensionality and impact of the piece, giving it a richer, more gallery-ready presentation.

Advanced matting techniques can support higher-tier quotes while reinforcing the added time, skill, and materials value.

Real-World Pricing Scenarios for Matting Techniques

Let’s consider a 16" x 20" custom frame job to understand how margins change with each layer. Your shop pays $16 for a 32" x 40" premium matboard from a top vendor and charges $25 per hour for labor. Other materials — like glass, backing board, moulding, and mounting supplies — average about $30 per piece.

You use roughly ¼ of the matboard sheet ($4) and spend about 10 minutes on labor for a single mat. That’s enough to calculate the full cost and return percentage.

Here’s how to break that down:

-

Add material costs: Include $4 for matboard and $30 for other materials to get $34 in base supply costs.

-

Calculate labor: Use the $25/hour rate — 10 minutes of work adds $4.17 in labor cost for measuring, cutting, and fitting a single mat.

-

Find total production cost: Combine materials and labor for a full production cost of $38.17.

-

Set a retail fee: Choose a price that reflects the matting complexity and material investment — in this case, $70 offers a good return for a single mat.

-

Calculate profit margin: Divide the profit by the retail price to get your markup percent — ($70 - $38.17) ÷ $70 = 45.5%.

Once you have that baseline, comparing potential income for other matting techniques is easy. Double matting brings total production costs to $46.33 with $8 for matboard and supplies, $8.33 for 20 minutes of labor at $25/hour, and $30 for glass, backing, and other materials. Selling that job for $110 gives you a 57.8% margin (($110 - $46.33) ÷ $110).

Triple matting raises production costs to about $52.42. That includes $12 in matboard, $30 for backing, glass, and hardware, and $10.42 for 25 minutes of labor at $25/hour. Pricing the job at $200 gives you a 73.8% margin (($200 - $52.42) ÷ $200).

How To Upsell Customers on Premium Matting Options

Some customers hesitate when they see a higher price for double or triple matting. But once they understand how they affect the look, protect the piece, and tie the whole frame together, it’s easier for them to say yes.

Use these strategies to gently upsell during your consultations:

-

Show visual examples: Use side-by-side comparisons or digital mockups to demonstrate how single, double, and triple mats affect depth, contrast, and overall impact. Let the artwork speak for itself.

-

Explain preservation benefits: Describe how added layers create space between the art and glass, reducing moisture and acid exposure. Emphasize the role of conservation materials in keeping the piece protected over time.

-

Offer design choices: Walk through color combinations, bevel sizes, and surface textures to show how matting can bring out specific tones in the artwork or tie in with the moulding — turning it into a design decision, not just a cost addition.

-

Frame the long-term value: Explain how upgraded matting enhances presentation, protects the artwork over time, and adds impact in any setting — from homes to galleries to gifts.

The goal is to show what makes the upgrade worth it. Most people are willing to spend more when they see and understand what they’re paying for.

Protect Your Revenue With Point of Sale (POS) Software

Even experienced framers may undervalue their work. Material costs fluctuate, waste accumulates, and fast quotes often overlook the actual time and effort required. But framing-specific POS software like LifeSaver helps you price custom jobs accurately every time.

This industry-specific point of sale system lets you:

-

Track materials used on each job: Record exactly which matboards and supplies went into the frame, including scrap and excess, so your pricing covers the full material cost for every job.

-

Calculate labor automatically: Use actual time spent on the job to generate labor costs based on your shop rate, helping you avoid undercharging for more complex builds.

-

Organize project details clearly: Enter matting layers, colors, and textures into your work order in the POS system before the job starts to avoid mistakes, miscommunication, and material waste.

-

Keep a record of customer approvals: Log every upgrade and sign off in the system to avoid confusion, chargebacks, or unpaid changes after the job is done.

With automated pricing tools, customers receive clear, reliable quotes, and your shop earns more on every custom project.

Make the Most of Matting Technique Pricing With LifeSaver

Matting techniques like single, double, or triple layers can offer significant returns for your framing business — but only if you list them at the right price. To do that, you need a tailored system to keep every detail organized from quote to pickup.

LifeSaver makes that easy. It tracks materials by job, calculates labor automatically, and generates detailed work orders that include every matting layer, color, and cut. Integrated visualization with FrameVue lets customers see digital mockups instantly to approve upgrades on the spot.

Never miss another chance to grow your margins. Try LifeSaver free for 14 days and start scaling your profits on every custom frame job.

Aug 26, 2025 9:15:45 PM